An ever-evolving research and partnership

The University of Greenwich was pleased to welcome big employers, including project partners, to its Medway Campus for an industrial workshop on collaborative robotics in manufacturing. The day was organised by engineering researcher Lancelot Martin and his supervisor at the university, Medway Chair of Manufacturing Engineering Professor James Gao, and consisted of a tour of the Automation and Industrial Robotics (AIR) laboratory; demonstrations of industrial robots and the working KANBAN system; an interactive session and technical presentations and discussions between the university research team and its industrial partners.

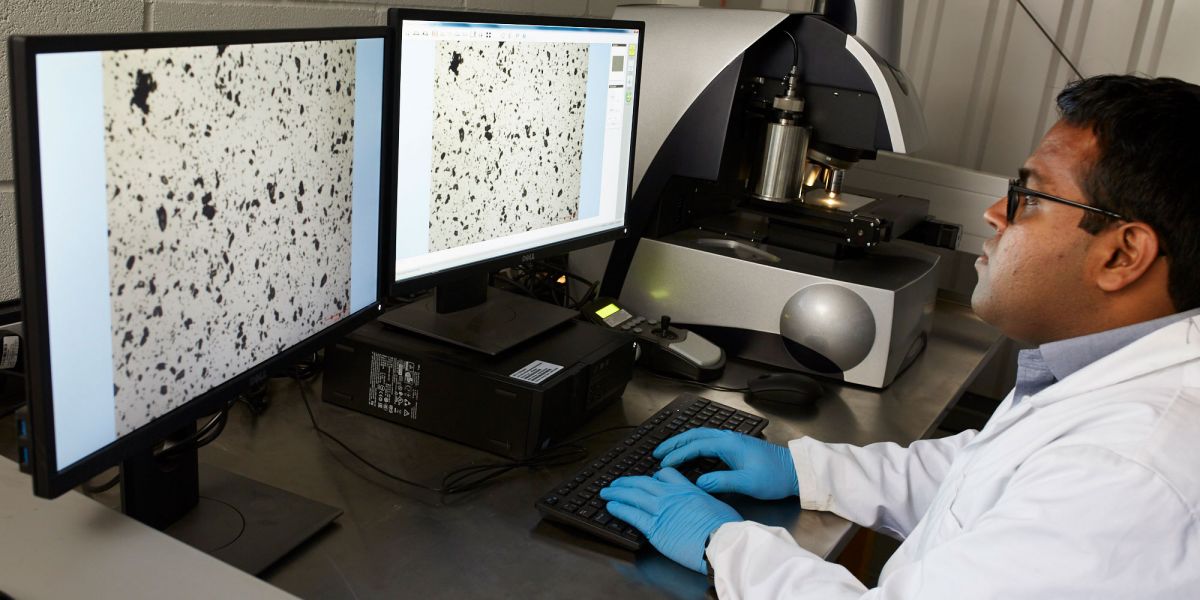

The origins of the state of art AIR laboratory that brought the University of Greenwich together with these companies on this day can be found in 2020, when the research team was awarded a major grant from UKRI ‘World Class Laboratory’ fund and purchased their first collaborative and mobile robot from robotics and automation company RARUK. The AIR laboratory was further developed with funding from the EU Interreg project CoRoT (corot-project.org) involving many academic and industrial partners from UK and France. The MiR100 robot was used in our research on the Medway Campus into safety in high occupancy mixed-use facilities, in collaboration with electric systems business BAE Systems Rochester, sponsor of several PhD projects. An important question arose from the research – could this robot be used to effectively deliver materials around tight and complex-shaped corridors of high value manufacturing facilities when people and robots operate simultaneously?

Collaborative working case study

Lancelot began to investigate and identified that sensors and presence detectors already present in the BAE Systems facility could be used to alert the robot to obstacles. Lancelot also explored converting fire safety regulations into safety routines that the robot could follow during a fire alarm. Recently, the team received an arm and base integration module from Denmark-based company Enabled Robotics (ER) with their software, as well as a robot fleet computer and self-charging station from RARUK. Another international addition to the team was Antoine Sarrazin, a Mechanical Engineering student from the University of Angers in France, who joined the University of Greenwich as an intern. The group requested access to ER’s pre-release software, specifically to work on a joint project with BAE systems, and the collaborative work case study was born.

The case study would have benefits for all involved. Lancelot, Antoine and Professor Gao would be able to further their research; BAE Systems would see improvements in the pre-release software they would be using, and ER would obtain valuable user feedback for future technology development. The case study went ahead, and the group are pleased to report that at testing stage the robot successfully delivered 102 boxes in under seven hours, well above its target. At the industrial workshop, the project came together with all partners involved on-site or in virtual attendance to see the robot in action and continue discussions. Cummins Power Generation Limited, MEP Ltd, Fujitsu and Atlas Copco were also welcomed. Several of these companies have previously worked with the University of Greenwich in sponsoring engineering PhD students.

Benefits for staff and students

The University of Greenwich is proud to be working collaboratively – a core value of the university – with so many employers and agencies both nationally and internationally on this innovative and highly promising developing research.

Strong partnerships with employers have created research and employability opportunities for University of Greenwich staff and students across campuses, and its research has achieved outstanding REF results.

The university has a dedicated enterprise development team, and also has many postgraduate research students (PGRs), who can join the university through externally advertised projects or self-funded projects. The university requests students make contact with the academic they would like to supervise their project prior to submitting an application.