Cellular Automata Modelling for simulating segregation of wood pellets in silo filling and discharge

Wood pellets are widely used in power generation, often co-fired in traditional coal fired power stations. Wood pellets are a low carbon energy resource which can naturally be replenished. Wood pellets are handled often by conventional coal handling equipment such as conveyer belts, pneumatic conveyors, and frequently stored in large silos and domes. During handling and storing, wood pellets degrade into fines and dust. Wood pellets mixed with fines and dust have a tendency to segregate in handling, especially silo filling and discharge. This causes spikes in fines and dust level which result in suboptimal pneumatic conveying (high energy consumption).

Due to variable operational conditions, dust escape from processes can be more problematic, leading to dust accumulation in the environment, requiring more intense cleaning. Moreover, it leads to increased risk of fire and explosion. Unsteady unit operations including particle milling may consume excess amount of energy, resulting in additional cost in parasitic load. In this study, segregation during silo filling and discharge was modelled using Cellular Automata (CA) approach. CA modelling is a mechanistic, deterministic approach, in this case using a simple set of rules derived based on close observation of particle heap formation and free surface segregation.

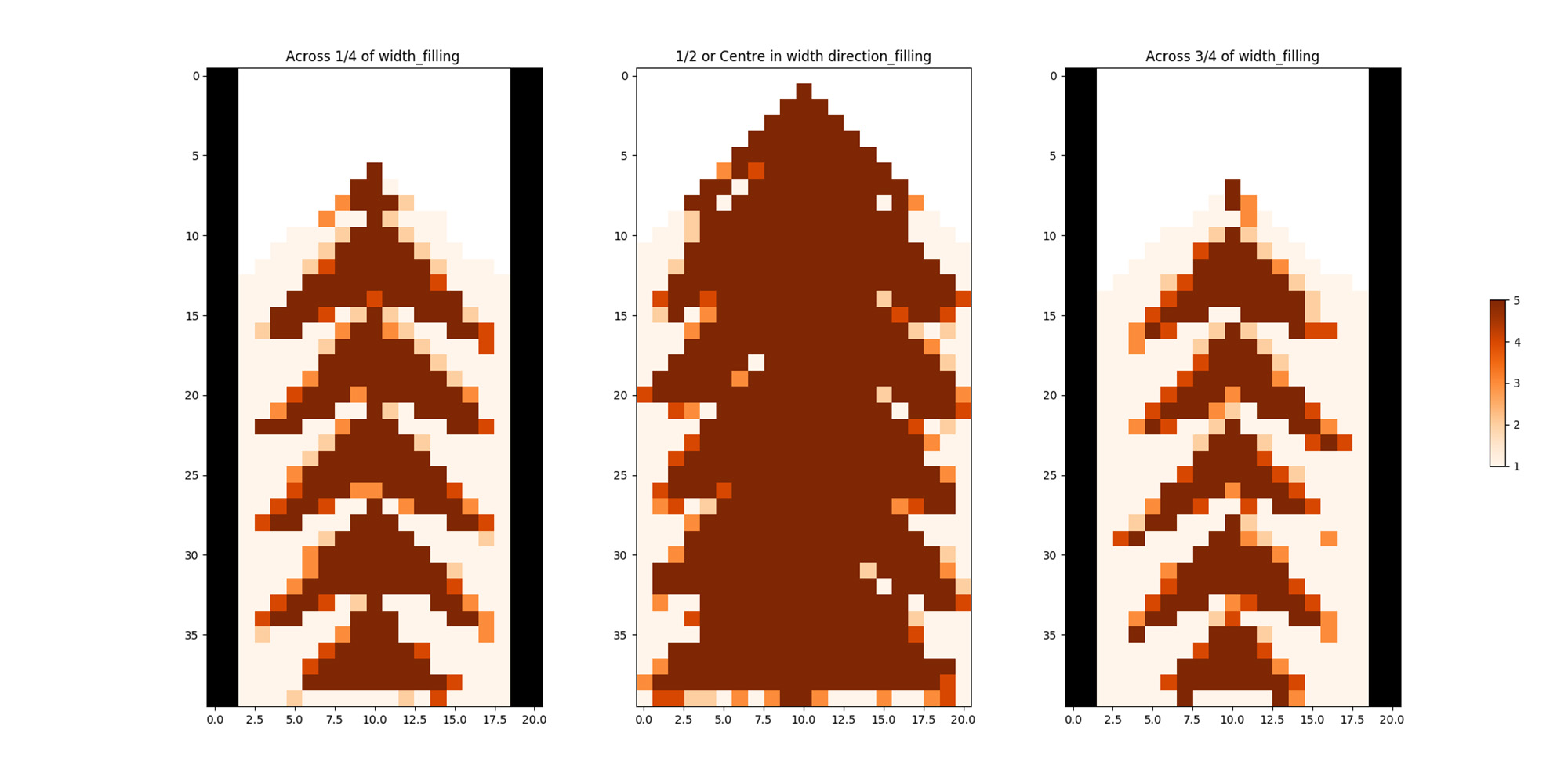

The aim of this study was to test the suitability of CA modelling for estimating segregation in bulk material handling. 2-D simulations have been developed using Excel VBA and tested against laboratory scale test rigs. These CA models have shown an excellent capability to predict segregation in silo filling and discharge. All key features of behaviour seen in the experiments are captured in the model; in filling, due to free surface segregation, higher level of fines was predicted under the feeding point (usually the centre of the silo), and in discharge the tendency for fines to sift downwards through the moving layer is also captured.