This course is available in-company. Please contact us for details.

Course overview

The drawing up of specifications and correct design of hoppers, silos, bunkers and other large scale bulk storage schemes is of fundamental importance for the optimal operation of plant. Many processes fail to reach their designed throughput or suffer from 'unforeseen' handling problems. The root cause of a very large proportion of these issues can be traced back to a failure to understand the storage and handling requirements of the bulk materials and hence installations that do not incorporate bulk characteristics into the design process may encounter these issues.

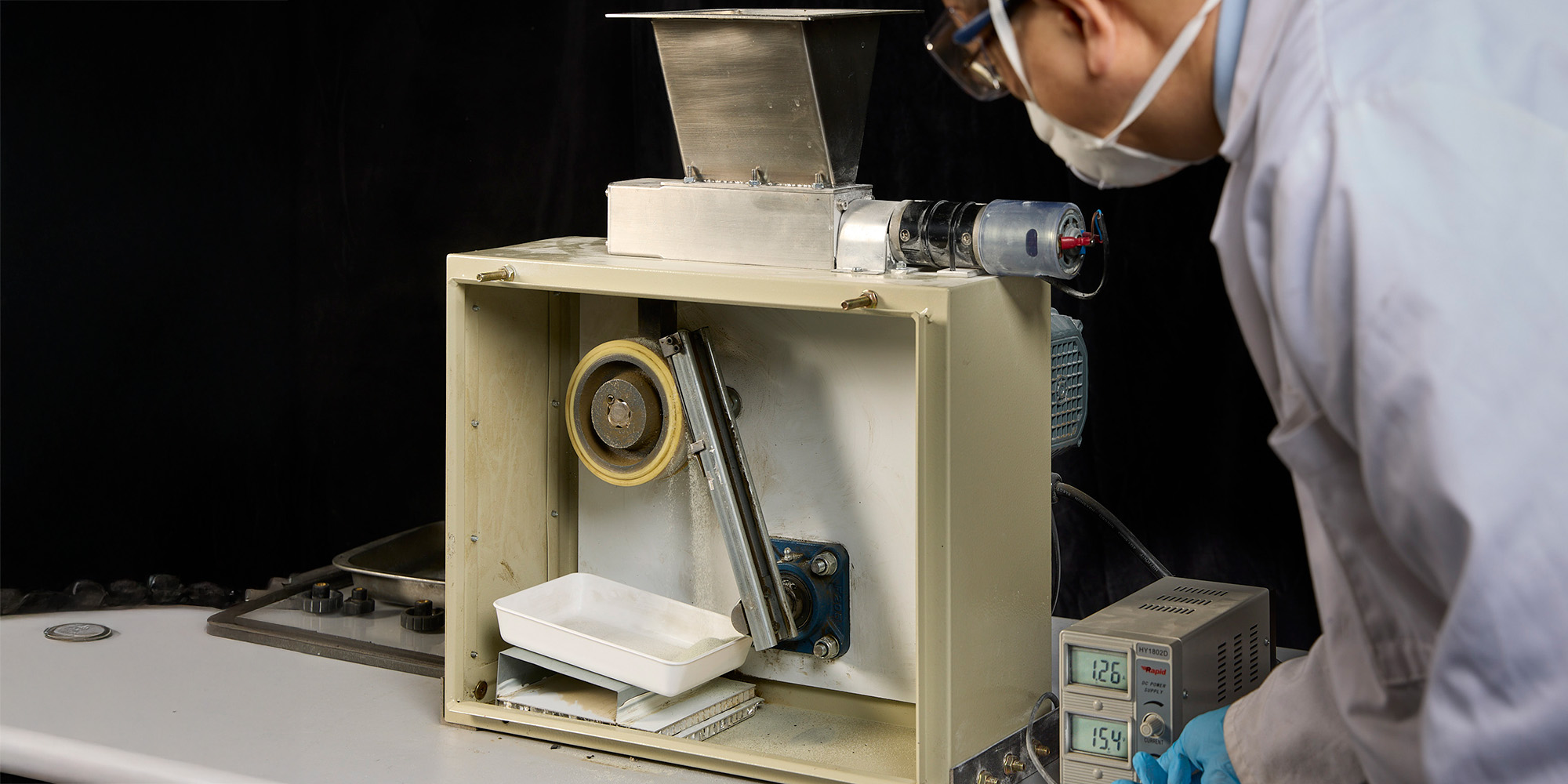

This course has been developed with specification writers and equipment designers/suppliers in mind. Practical and 'hands-on' exercises will feature in the course structure.

Subjects covered

- Minimising project risk through characterisation of bulk materials;

- How to characterise bulk materials using firmly established methods and the latest test equipment;

- How to use shear cell measurements to design for reliable discharge;

- Detail design for storage equipment;

- Best Practice for bulk handling plant design and operation;

- When should discharge aids be applied and appropriate types;

- Methods for correct interfacing.

Is this for me?

This course is intended to target project engineers involved in the detail specification of bulk handling schemes or design engineers involved in the construction of equipment used for storing bulk materials. The content of the course will also be of relevance to engineers that wish to be brought up to speed with equipment and operational best practice relating to bulk handling.

If you are new to the subject we would recommend attendance at our standard storage and discharge of powders and bulk materials course first, which gives an overview of the subject and sets out the basics upon which this course builds.

Venue

The course can be delivered at your premises or online.

Course team

The course leader is Dr Baldeep Kaur, whose interests lie in characterisation and transportation of bulk materials;

Contributions may also be made from the rest of the Team, including

Mike Bradley, Professor of Bulk and Particulate Technologies and Director of The Wolfson Centre. He has worked internationally on design and troubleshooting of bulk solids handling as a commercial consultant and research expert for over thirty years;

Dr Atul Sharma, whose interests lie in pneumatic conveying systems.

Dr Vivek Garg, whose interests lie in powder flowability;

Dr Hamed Johnny Sarnavi, whose interest lie in classification and drying techniques.

Please note that The Wolfson Centre reserves the right to substitute leaders of equal quality should this be dictated by circumstances beyond their control.

In-Company course

This course can be delivered as an In-Company course on line at a time to suit operational requirements.

These are proving to be a popular option for companies who have a number of personnel who would benefit from education in the subject area, for 3 main reasons:

- Cost: It is more economic for us to bring the course to you, than for you to send several staff out to us;

- Relevance: We can tailor the course programme to suit the operations you have in your plant, hence reducing the amount of material which is not directly relevant;

- Convenience: We can run the course when it suits you, even over several separate days rather than in a block if it is better for you.

If you are interested in discussing your requirements, please contact us.