Course overview

There is an increasing interest in different modelling techniques available both in industry and academe, but there is little information about how to choose the best approach for any given problem. Consequently it can be difficult and time consuming to get sensible results, particularly where a particular model may have worked perfectly well for one problem, then fails on another to which it is ill-suited.

The Wolfson Centre for Bulk Solids Handling Technology are users of a number of different modelling approaches. Their experts have teamed up with other departmental experts within the University to bring together a course where they can showcase some of these different modelling methods, what the names mean, and what they are good for.

Format

The course comprises classroom-based learning about the different models, as well as a workshop whereby delegates will use the different models to practice the theories of the previous day. All IT equipment will be provided for the workshop. Case studies will be used throughout, where appropriate. Current research and future prospects will form part of the content.

Subjects covered

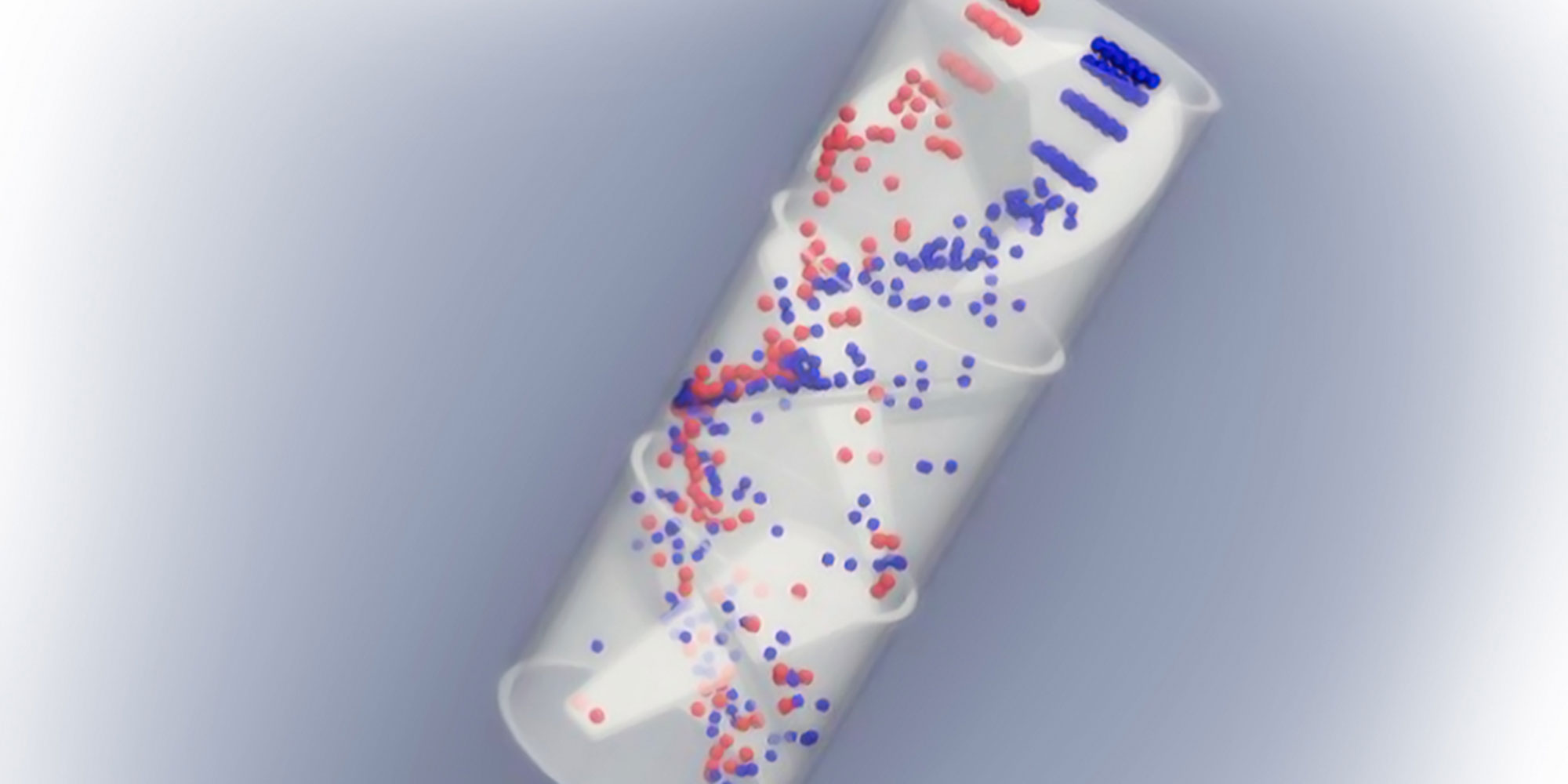

- DEM

- Population Balance Modelling

- Cellular Automata

- Finite Difference Modelling

- CFD - Both Euler-Euler and Euler-Lagrange

For each modelling technique the course will cover:

- how they work,

- key principles,

- the key parameterisation and calibration factors and how they relate to particle or bulk characterisations,

- an explanation of what problems and design challenges they are good for solving and their limitations, and

- relevant case study/studies.

Is it for me?

The course would be ideal for individuals both in research and industry who are relatively new to modelling and would like to understand how these different methods relate to one another, and which to choose to solve their specific problems.

Venue

The course can be held at the University of Greenwich Medway campus, Chatham Maritime, Kent

Course team

The course leader is Mike Bradley, Professor of Bulk and Particulate Technologies and Director of The Wolfson Centre. He has worked internationally on design and troubleshooting for bulk solids handling as a commercial consultant and research expert for over thirty years.

Contributions may also be made from the rest of the Team, including

Dr Baldeep Kaur, whose interests lie in characterisation and transportation of bulk materials;

Dr Vivek Garg, whose interests lie in powder flowability;

Dr Atul Sharma, whose interests lie in pneumatic conveying systems.

Dr Hamed Johnny Sarnavi, whose interest lie in classification and drying techniques.

Please note that The Wolfson Centre reserves the right to substitute leaders of equal quality should this be dictated by circumstances beyond their control.

In-Company courses

Due to the Hands on nature of this course it is not possible to transfer the teaching to your site. However, it is possible for an In-Company course to be arranged at our campus to suit your requirements. Please contact us for details and course fees.